Umatshini wokuprinta we-CI Flexo

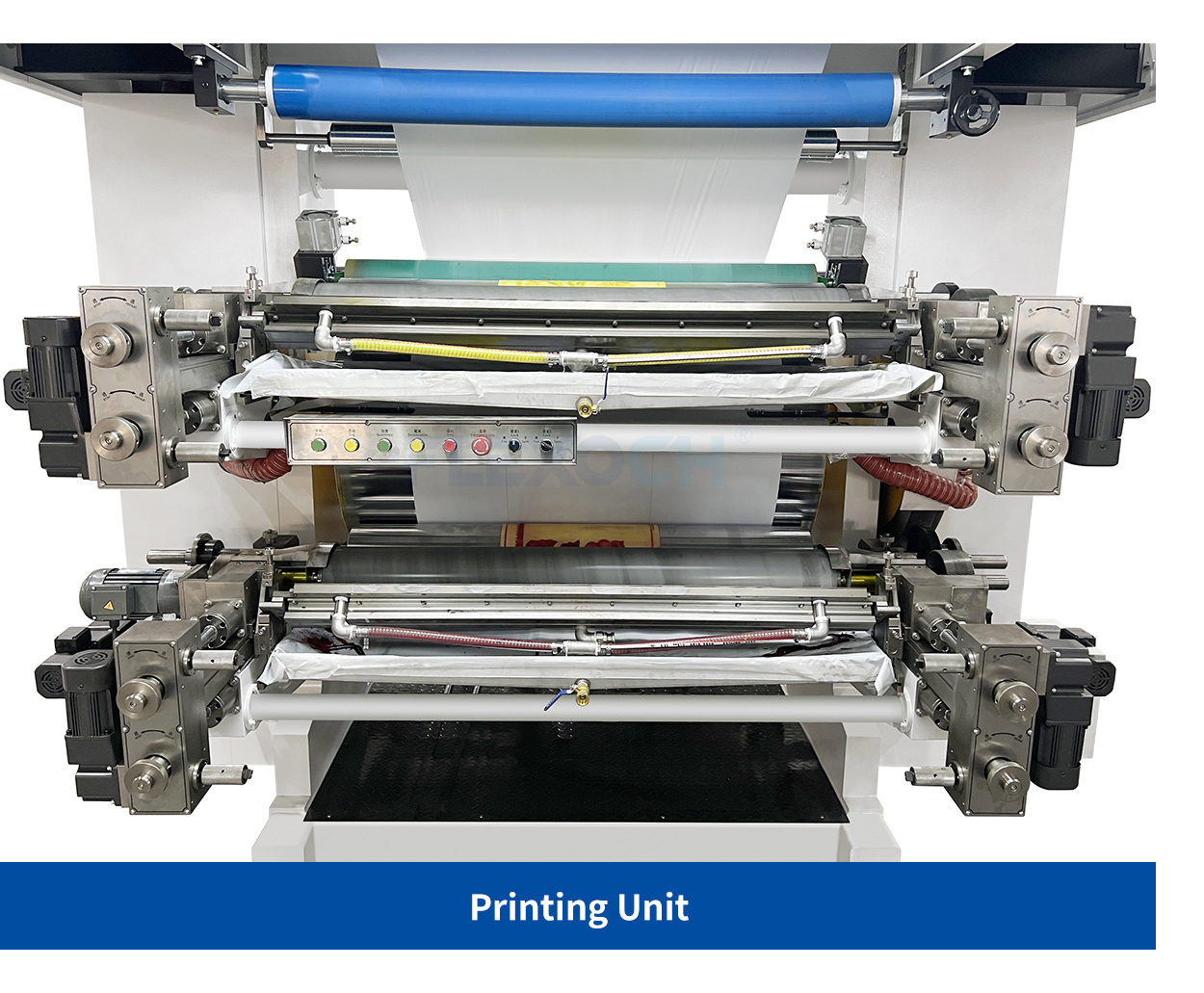

Umatshini wokuprinta we-CI (Central Impression) we-flexo usebenzisa idrama enye enkulu yokubamba izinto zizinzile ngelixa yonke imibala iprinta ngeenxa zonke. Olu yilo lugcina uxinzelelo luzinzile kwaye lubonelela ngokuchanekileyo kobhaliso, ngakumbi kwiifilimu ezinobuthathaka.

Isebenza ngokukhawuleza, ayichithi zinto zininzi, kwaye ivelisa iziphumo eziprintiweyo ezikumgangatho ophezulu—ifanelekile kwiipakethe zekhwalithi ephezulu kunye nezicelo ezichanekileyo.

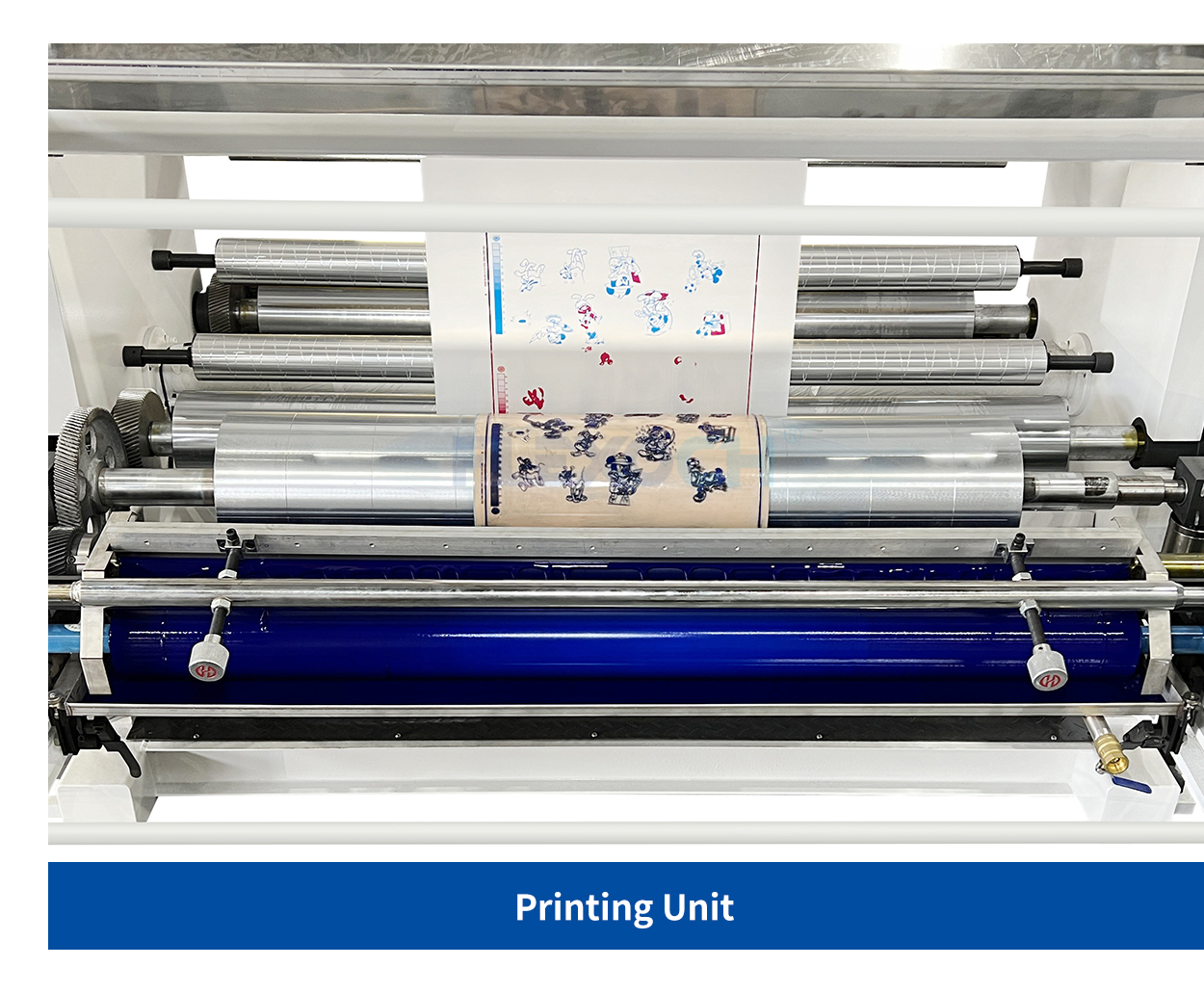

Umatshini wokuprinta weFlexo yohlobo lweStack Type

I-stack flexo press ineyunithi nganye yombala ecwangciswe ngokuthe nkqo, kwaye isikhululo ngasinye sinokulungiswa ngokwaso. Oku kwenza kube lula ukusingatha izixhobo ezahlukeneyo kunye notshintsho lomsebenzi. Isebenza kakuhle kwiintlobo ngeentlobo ze-substrates kwaye iluncedo ngakumbi ekuprinteni okumacala omabini.

Ukuba ufuna umatshini oguquguqukayo nongabizi kakhulu kwimisebenzi yokupakisha yemihla ngemihla, i-stack flexo press lukhetho olusebenzayo noluthembekileyo.

Nokuba ngumatshini wokuprinta we-CI flexo okanye umatshini wokuprinta we-flexo wohlobo lwe-stack, ukuchaneka kobhaliso lombala kunokwenzeka, okunokuchaphazela ukusebenza kombala kunye nomgangatho wokuprinta wemveliso yokugqibela. La manyathelo mahlanu alandelayo abonelela ngenkqubo ecwangcisiweyo yokusombulula iingxaki kunye nokusombulula le ngxaki.

1. Hlola Uzinzo LweeMechanical

Ukubhaliswa gwenxa kudla ngokubangelwa kukuguguleka koomatshini okanye ukuyekelela. Kwiimashini zokuprinta ze-stack flexo, kufanelekile ukuhlola rhoqo iigiya, iibheringi, kunye neebhanti zokuqhuba ezidibanisa iyunithi nganye yokuprinta, ukuqinisekisa ukuba akukho kudlala okanye i-offset enokuchaphazela ukulungelelaniswa.

Iimashini zokuprinta ezibonisa uphawu oluphakathi zihlala ziqinisekisa ubhaliso oluzinzileyo kuba yonke imibala iprintwa kwidrama enye ebonisa uphawu. Nangona kunjalo, ukuchaneka kusaxhomekeke ekufakeni isilinda yepleyiti ngokuchanekileyo kunye nokugcina uxinzelelo lwewebhu oluzinzileyo—ukuba nakuphi na ukutyibilika, uzinzo lobhaliso luya kuphazamiseka.

Ingcebiso:Nanini na xa iipleyiti zitshintshwa okanye umatshini ubungasebenzi okwethutyana, jika iyunithi nganye yokuprinta ngesandla ukuze uve naluphi na uxhathiso olungaqhelekanga. Emva kokugqiba ukulungisa, qala ucinezele ngesantya esiphantsi kwaye ujonge iimpawu zobhaliso. Oku kunceda ukuqinisekisa ukuba ulungelelwaniso luhlala luhambelana ngaphambi kokuba unyuselwe kwisantya esipheleleyo semveliso.

2. Lungiselela ukuhambelana kweSubstrate

Izinto ezinje ngefilimu, iphepha, kunye nezinto ezingezizo ezolukiweyo zisabela ngokwahlukileyo kuxinzelelo, kwaye olu tshintsho lunokubangela utshintsho lobhaliso ngexesha lokuprinta. Iimashini zokuprinta ze-CI flexographic zihlala zigcina uxinzelelo oluzinzileyo kwaye ke ngoko zilungele ukusetyenziswa kwefilimu ezifuna ukuchaneka okuqinileyo. Iimashini zokuprinta ze-stack flexo, ngokwahlukileyo, zihlala zifuna ukulungiswa ngokuchanekileyo kwezicwangciso zoxinzelelo ukuze zihlale zihambelana.

Ingcebiso:Xa ubona ukuba izinto zisolula okanye zincipha ngokubonakalayo, nciphisa uxinzelelo lwewebhu. Uxinzelelo oluphantsi lunokunceda ekunciphiseni utshintsho lobukhulu kunye nokunciphisa utshintsho lobhaliso.

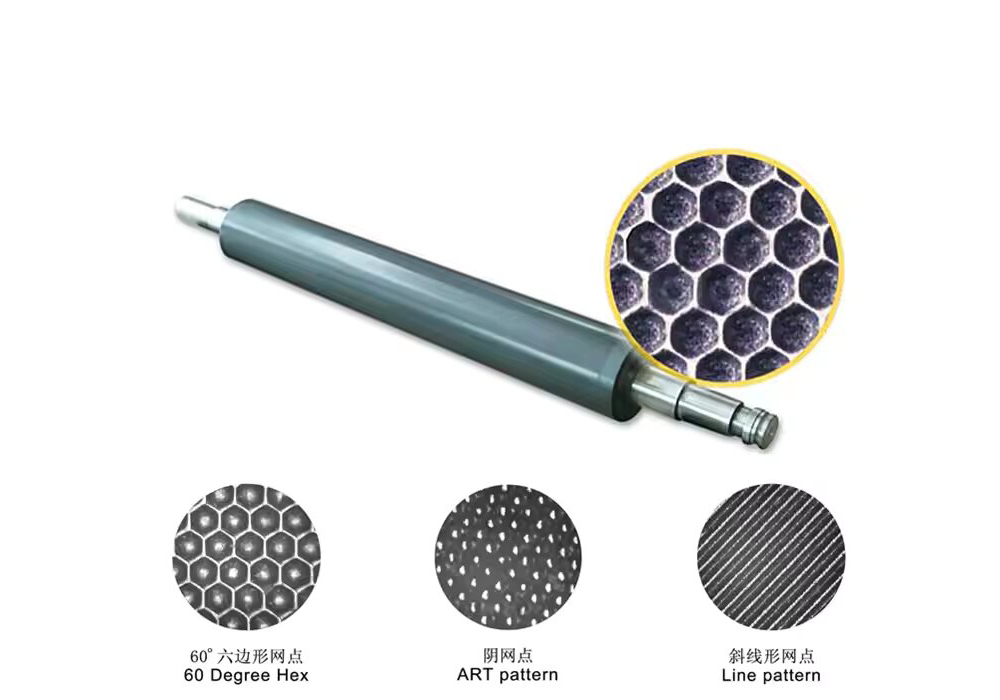

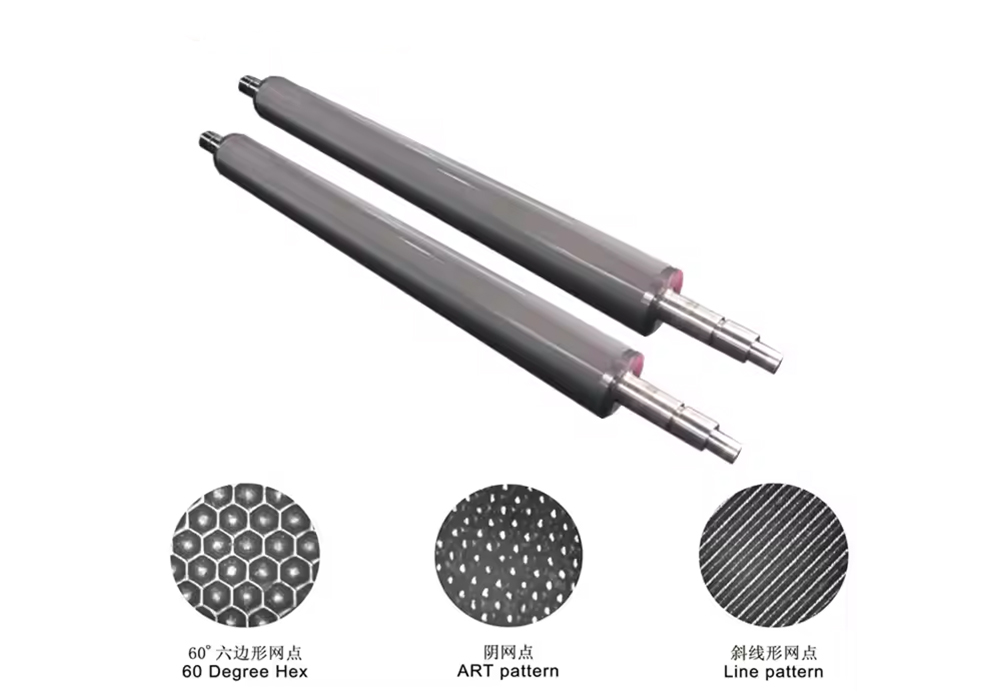

3. Ukuhambelana kwePlate kunye neAnilox Roll

Iimpawu zepleyiti—ezifana nobukhulu, ubulukhuni, kunye nokuchaneka kokukrola—zinefuthe ngqo ekusebenzeni kobhaliso. Ukusebenzisa iipleyiti ezinesisombululo esiphezulu kunokunceda ukulawula ukufunyanwa kwamachaphaza nokuphucula uzinzo. Inani lomgca we-anilox roll likwafuneka lihambelane ngononophelo nepleyiti: inani lomgca ophezulu kakhulu linokunciphisa umthamo we-inki, ngelixa inani eliphantsi kakhulu linokubangela i-inki egqithisileyo kunye nokukrala, zombini ezo zinto zinokuchaphazela ngokungathanga ngqo ukulungelelaniswa kobhaliso.

Ingcebiso:Kungcono ukulawula inani lemigca yerola ye-anilox kwi-100 - 1000 LPI. Qinisekisa ukuba ubunzima bepleyiti buhlala bufana kuzo zonke iiyunithi ukuze kuthintelwe ukwanda kwezi nguqu.

4. Lungisa uxinzelelo lokuprinta kunye nenkqubo yokuyila

Xa uxinzelelo lomfanekiso lubekwe phezulu kakhulu, iipleyiti zokuprinta zinokonakala, kwaye le ngxaki ixhaphake kakhulu kumatshini wokuprinta we-flexo wohlobo lwe-stack, apho isikhululo ngasinye sifaka uxinzelelo ngokwaso. Misela uxinzelelo lweyunithi nganye ngokwahlukileyo kwaye usebenzise kuphela ubuncinci obufunekayo ekudluliseleni umfanekiso ococekileyo. Ukuziphatha kwe-inki ezinzileyo kukwadlala indima ebalulekileyo kulawulo lobhaliso. Jonga i-engile yeblade kagqirha kwaye ugcine i-viscosity ye-inki efanelekileyo ukuze uphephe ukusasazwa kwe-inki okungalinganiyo, okunokubangela utshintsho lobhaliso lwendawo.

Ingcebiso:Kuzo zombini iintlobo ze-stack kunye nomatshini wokuprinta we-CI flexographic, indlela emfutshane ye-inki kunye nokudluliselwa kwe-inki ngokukhawuleza kwandisa uvakalelo kwiimpawu zokomisa. Jonga isantya sokomisa ngexesha lokuveliswa, kwaye ufake i-retarder ukuba i-inki iqala ukoma ngokukhawuleza.

● Intshayelelo yevidiyo

5. Sebenzisa izixhobo zokubhalisa ngokuzenzekelayo kunye nembuyekezo

Iimashini zokuprinta ze-flexographic zanamhlanje ziquka iimpawu zokubhalisa ngokuzenzekelayo ezilungisa ulungelelwaniso ngexesha langempela ngelixa imveliso isebenza. Ukuba iingxaki zolungelelwaniso zisaqhubeka emva kohlengahlengiso olwenziwe ngesandla, zinike ixesha lokuphonononga iirekhodi zomsebenzi zangaphambili. Ukujonga idatha yemveliso yembali kunokufumanisa iipateni eziphindaphindayo okanye ukuphambuka okunxulumene nexesha okubonisa unobangela oyintloko, kukunceda wenze utshintsho olugxile ngakumbi nolusebenzayo lokuseta.

Ingcebiso:Kwiipress ebezisebenza ixesha elide, kufanelekile ukwenza uhlolo olupheleleyo lolungelelwaniso oluthe tye kuzo zonke iiyunithi zokuprinta ngamanye amaxesha. Eli nyathelo libaluleke kakhulu kwiipress zohlobo lwe-stack flexo, kuba isikhululo ngasinye sisebenza ngokuzimeleyo kwaye ubhaliso oluhambelanayo luxhomekeke ekuzigcineni zilungelelaniswe njengenkqubo edibeneyo.

Isiphelo

Nokuba ngumatshini wokuprinta we-flexographic ophakathi okanye umatshini wokuprinta we-flexo wohlobo lwe-stack, ingxaki yokubhalisa umbala idla ngokubangelwa kukusebenzisana kwezinto eziguquguqukayo zoomatshini, izinto kunye neenkqubo, endaweni yento enye. Ngokulungisa iingxaki ngendlela ecwangcisiweyo kunye nokulinganisa ngononophelo, sikholelwa ukuba unokunceda ngokukhawuleza umatshini wokuprinta we-flexographic ukuba uqalise ukuvelisa kwaye uphucule uzinzo lwexesha elide lwezixhobo.

Ixesha lokuthumela: Agasti-08-2025