Kwinkqubo yoomatshini be-flexographic, ukomisa i-inki kancinci okukhokelela ekutshixeni kube ngumceli mngeni oqhubekayo kwiinkampani zokuprinta. Oku akuchaphazeli nje kuphela umgangatho wokuprinta kwaye kwandisa inkunkuma kodwa kunciphisa nokusebenza kakuhle kwemveliso kwaye kunokulibazisa neeshedyuli zokuhambisa. Le ngxaki ingasonjululwa njani ngempumelelo? Sinikezela ngesisombululo esibanzi esigubungela ukukhethwa kwe-inki, ukulungiswa kwenkqubo, ukuphuculwa kwezixhobo, kunye nolawulo lokusingqongileyo ukukunceda uphelise ukutshixeni kwaye ufezekise imveliso yokuprinta ezinzileyo nesebenza kakuhle.

Kwinkqubo yoomatshini be-flexographic, ukomisa i-inki kancinci okukhokelela ekutshixeni kube ngumceli mngeni oqhubekayo kwiinkampani zokuprinta. Oku akuchaphazeli nje kuphela umgangatho wokuprinta kwaye kwandisa inkunkuma kodwa kunciphisa nokusebenza kakuhle kwemveliso kwaye kunokulibazisa neeshedyuli zokuhambisa. Le ngxaki ingasonjululwa njani ngempumelelo? Sinikezela ngesisombululo esibanzi esigubungela ukukhethwa kwe-inki, ukulungiswa kwenkqubo, ukuphuculwa kwezixhobo, kunye nolawulo lokusingqongileyo ukukunceda uphelise ukutshixeni kwaye ufezekise imveliso yokuprinta ezinzileyo nesebenza kakuhle.

● Ukukhethwa kwe-Ink kunye nokuphucula iFomula – Ukusombulula iingxaki zokumisa kwindawo yomthombo

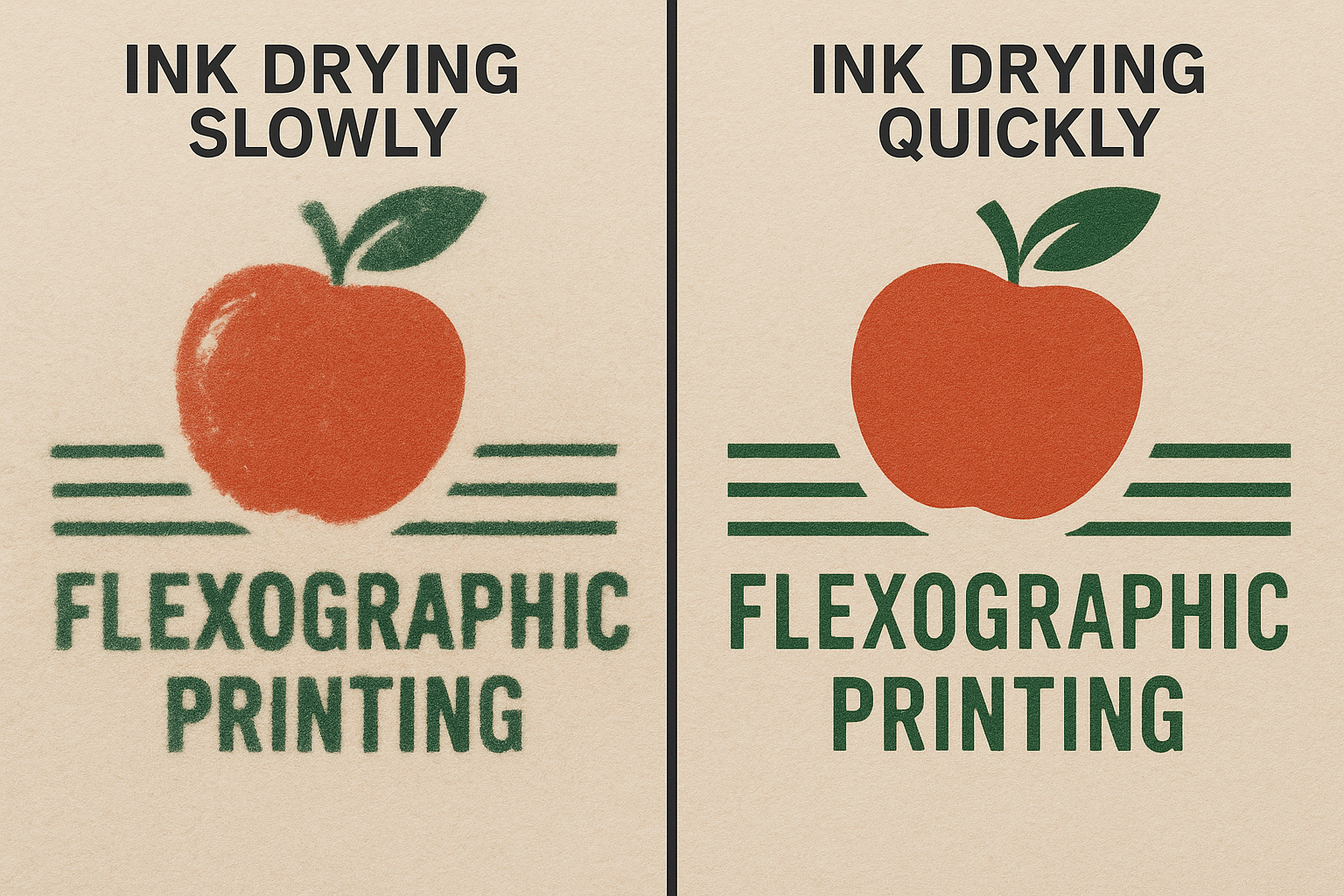

Kwimishini yokuprinta i-flexo, ukukhetha kunye nokwakheka kwe-inki kubalulekile ekusombululeni iingxaki zokomisa. Sicebisa ii-inki ezomisa ngokukhawuleza, ezifana nee-inki ezisekwe kwi-solvent ezine-formulations eziguquguqukayo kakhulu okanye ii-inki ezisekwe emanzini ezine-accelerators zokomisa. Ukuze ufumane isantya esiphezulu sokomisa, ii-inki ze-UV ezidityaniswe neenkqubo zokomisa ze-ultraviolet zezona zilungileyo. Ukulungisa ii-solvent ratios—ezifana nokunyusa umxholo we-ethanol okanye i-ethyl acetate—kunokuphucula ukusebenza kokomisa ngelixa kugcinwa uzinzo lwe-inki. Ukongeza, ukukhetha izongezo ezifanelekileyo zokomisa (umz., izomisi ze-cobalt/manganese kwii-inki zokomisa ze-oxidative okanye ii-penetrants ezikhethekileyo ze-substrates ezifunxayo) kuqinisekisa iziphumo ezilungileyo.

● Ukuphuculwa kweNkqubo yokomisa – Ukuphucula ukusebenza kakuhle

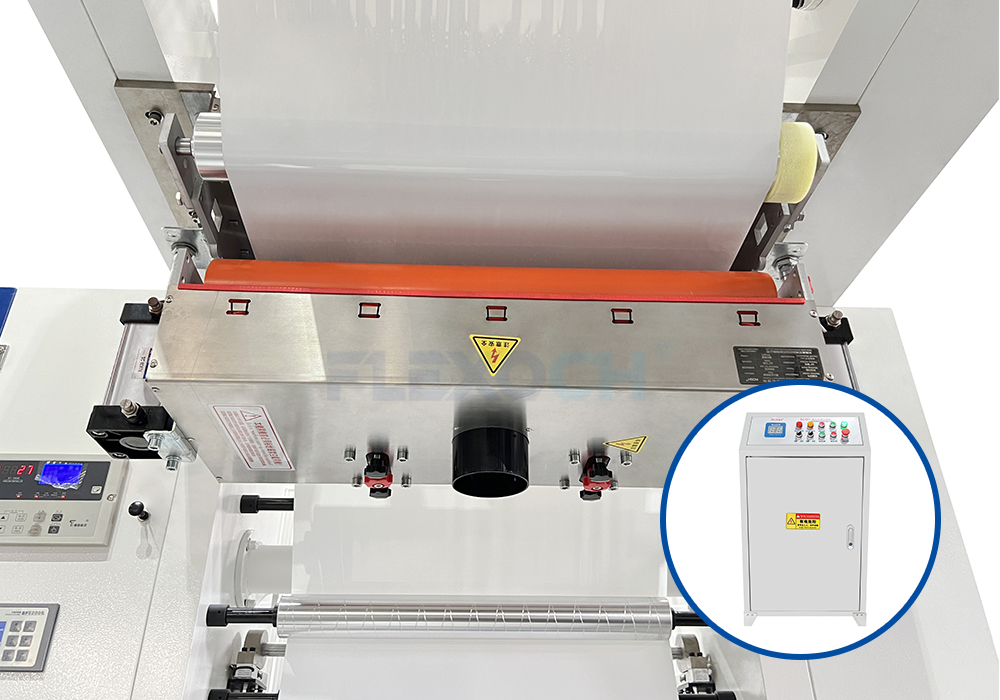

Ukusebenza kweenkqubo zokomisa kumatshini wokuprinta we-flexo kuchaphazela ngqo iziphumo. Hlola rhoqo ii-dryer ukuqinisekisa ukuba ubushushu bufanelekile (50–80°C kwii-inki ze-solvent, ziphantsi kancinci kwii-inki ezisekelwe emanzini) kunye nokuhamba komoya okungaphazanyiswanga. Kwizicelo ezifuna amandla, phucula ukomisa nge-infrared ukuze usebenze kakuhle kwindawo ethile okanye ucime i-UV ukuze womise ngoko nangoko. Iiyunithi zokomisa ngomoya obandayo ziluncedo kakhulu kwiifilimu ezingafunxiyo ukuthintela ukumanzisa kwakhona kwe-inki.

● Ukuphucula Inkqubo Yokuprinta – Ukulungisa iiParamitha Zemveliso

Kwiimashini zokuprinta ze-flexographic, ukuphucula iiparameter zemveliso kuphucula kakhulu ukusebenza kakuhle kokomisa. Ukulawula isantya sokuprinta kubalulekile—isantya esigqithisileyo sithintela ukoma ngokufanelekileyo ngaphambi kwesitishi esilandelayo sokuprinta. Lungisa isantya ngokusekelwe kwiimpawu ze-inki kunye nomthamo wokomisa. Ukulawula ubukhulu befilimu ye-inki ngokukhetha i-anilox roller ngokufanelekileyo kunye nomthamo we-inki kuthintela ukwakheka okugqithisileyo. Kwiprinta enemibala emininzi, ukwandisa isithuba sesitishi okanye ukongeza ii-interstation dryers kwandisa ixesha lokomisa.

● Uhlengahlengiso lweNdalo kunye neSubstrate – Izinto ezibalulekileyo zangaphandle

Iimeko zendalo kwimisebenzi yeprinta ye-flexo zichaphazela kakhulu ukomisa. Gcina ubushushu bomgangatho wevenkile bungama-20–25°C kunye nomswakama kuma-50–60%. Sebenzisa izixhobo zokususa umswakama ngamaxesha onyaka anomswakama. Unyango lwangaphambi kokusetyenziswa kwe-substrate (umz., unyango lwe-corona kwiifilimu ze-PE/PET) luphucula ukunamathela kwe-inki kwaye lunciphisa iziphene zokomisa.

Unyango lweCorona

Ulawulo lokufuma

Okokugqibela, isicwangciso sokugcina esiqinileyo siqinisekisa uzinzo lwexesha elide. Coca rhoqo ii-nozzles zokomisa kunye nezinto zokufudumeza, uhlole ukuguguleka kwe-anilox roller, kwaye usebenzise abavavanyi boxinzelelo lokomisa ukujonga umgangatho wokuprinta—amanyathelo aphambili ekuthinteleni iingxaki ezinxulumene nokomisa.

Ixesha leposi: Meyi-29-2025