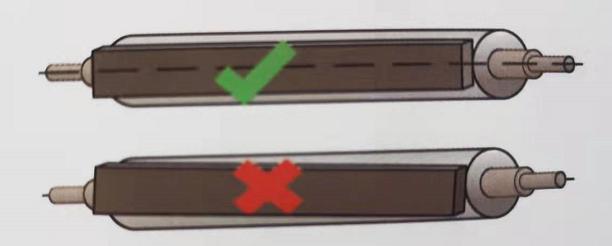

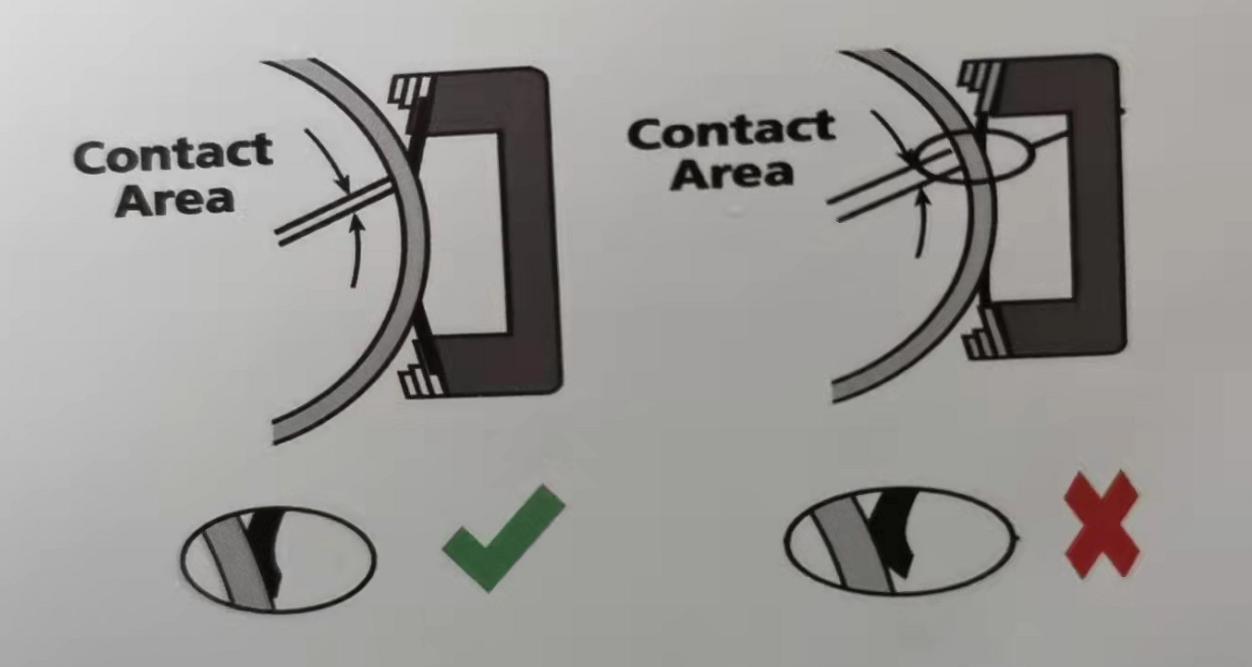

Ukuvaleka kweeseli ze-anilox roller ngokwenene yeyona nto ingenakuphepheka ekusebenziseni ii-anilox rollers, Iimpawu zayo zahlulwe zibe ziimeko ezimbini: ukuvaleka komphezulu we-anilox roller (Umfanekiso.1) kunye nokuvaleka kweeseli ze-anilox roller (Umfanekiso. 2).

Umfanekiso .1

Umfanekiso .2

Inkqubo ye-inki ye-flexo eqhelekileyo inegumbi le-inki (inkqubo yokutya i-inki evaliweyo), i-anilox roller, i-plate cylinder kunye ne-substrate. Kubalulekile ukuseka inkqubo yokudlulisa i-inki ezinzileyo phakathi kwe-inki Chamber, ii-anilox roller cells, umphezulu wamachaphaza e-printing plate kunye nomphezulu we-substrate ukuze kufunyanwe iiprinti ezisemgangathweni ophezulu. Kule ndlela yokudlulisa i-inki, izinga lokudlulisa i-inki ukusuka kwi-anilox roll ukuya kumphezulu we-plate limalunga ne-40%, ukudluliselwa kwe-inki ukusuka kwi-plate ukuya kwi-substrate limalunga ne-50%, Kuyabonakala ukuba ukudluliselwa kwe-inki enjalo akusiyo indlela elula yokudlulisa ebonakalayo, kodwa yinkqubo enzima equka ukudluliselwa kwe-inki, ukomisa i-inki, kunye nokuphinda kunyibilike i-inki; Njengoko isantya sokushicilela somatshini wokuprinta we-flexo sikhula ngokukhawuleza nangokukhawuleza, le nkqubo inzima ayizukuba nzima nje kuphela, kodwa kunye nokuphindaphinda kokuguquguquka kwindlela yokudlulisa i-inki kuya kuba ngokukhawuleza nangokukhawuleza; Iimfuneko zeempawu zomzimba zemingxunya nazo ziya ziphakama ngokunyuka.

Iipolymers ezineendlela zokudibanisa i-cross-linking zisetyenziswa kakhulu kwii-inki, ezifana ne-polyurethane, i-acrylic resin, njl.njl., ukuphucula ukunamathela, ukumelana nokukrweleka, ukumelana namanzi kunye nokumelana neekhemikhali zomaleko we-inki. Ekubeni izinga lokudluliselwa kwe-inki kwiiseli ze-anilox roller liyi-40% kuphela, Oko kukuthi, uninzi lwe-inki kwiiseli luhlala ezantsi kweeseli ngexesha lonke lenkqubo yokuprinta. Nokuba inxalenye ye-inki itshintshiwe, kulula ukuba i-inki igqitywe kwiiseli. Ukudibanisa i-resin cross-linking kwenziwa kumphezulu we-substrate, nto leyo ekhokelela ekuvalekeni kweeseli ze-anilox roll.

Kulula ukuqonda ukuba umphezulu we-anilox roller uvaliwe. Ngokubanzi, i-anilox roller ayisetyenziswa kakuhle, ukuze i-inki icocwe kwaye idityaniswe kumphezulu we-anilox roller, nto leyo ebangela ukuvaleka.

Kubavelisi beeroli ze-anilox, uphando nophuhliso lwetekhnoloji yokugquma i-ceramic, ukuphuculwa kwetekhnoloji yokusetyenziswa kwe-laser, kunye nokuphuculwa kwetekhnoloji yonyango lomphezulu we-ceramic emva kokukrolwa kweeroli ze-anilox kunokunciphisa ukuvaleka kweeseli zeroli ze-anilox. Okwangoku, iindlela ezisetyenziswa kakhulu kukunciphisa ububanzi bodonga lwe-mesh, ukuphucula ukugudama kodonga lwangaphakathi lwe-mesh, kunye nokuphucula ukuxinana kweroli ye-ceramic.

Kumashishini okushicilela, isantya sokomisa i-inki, ukunyibilika kwayo, kunye nomgama ukusuka kwindawo yokucinezela ukuya kwindawo yokuprinta nazo zinokulungiswa ukuze kuncitshiswe ukuvaleka kweeseli ze-anilox roller.

Ukugqwala

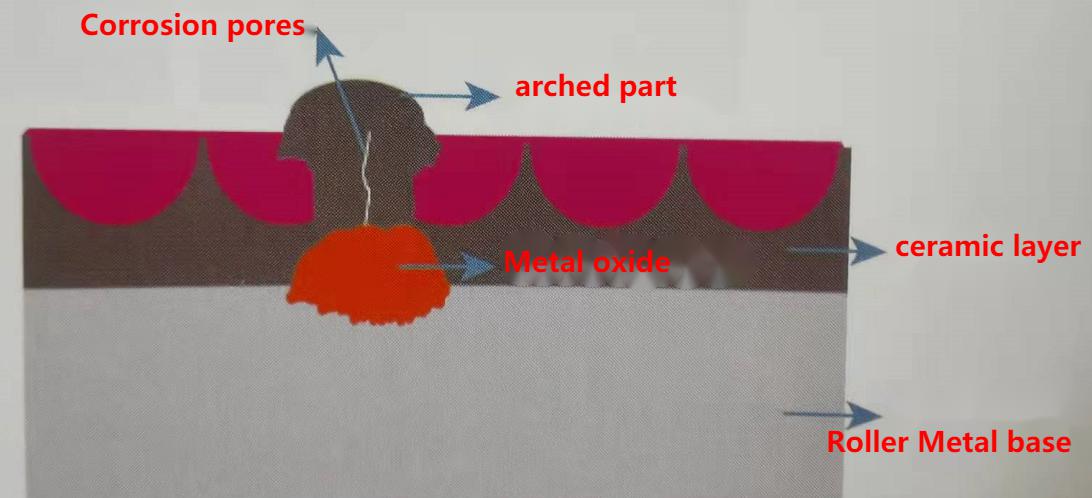

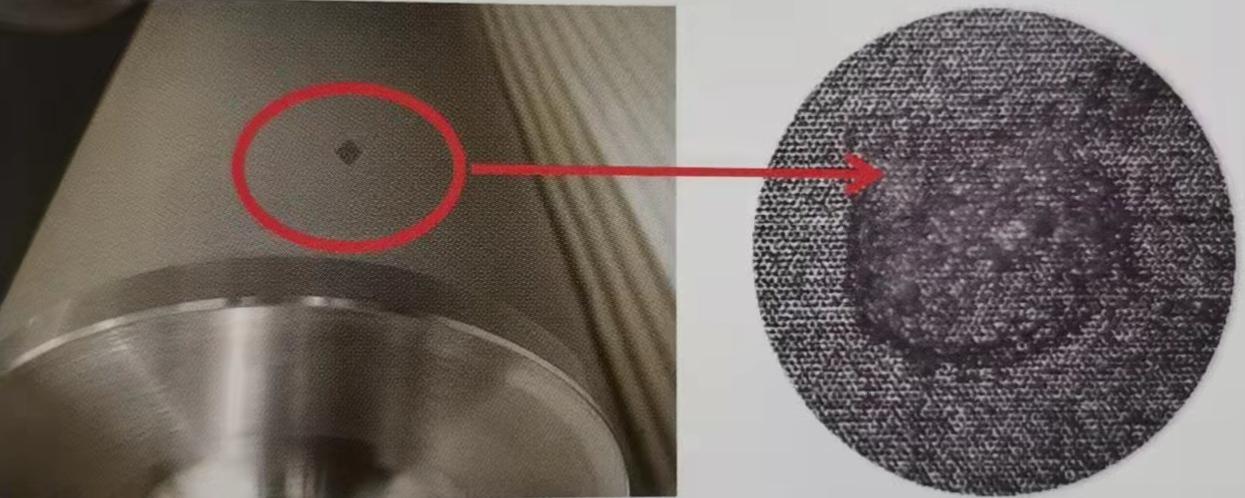

Ukubola kubhekisa kwisiganeko sokuvela okufana neengongoma kumphezulu werola ye-anilox, njengoko kubonisiwe kuMfanekiso 3. Ukubola kubangelwa yiarhente yokucoca engena kumaleko osezantsi ecaleni kwesithuba seseramikhi, ikonakalisa irola esisiseko sesinyithi esezantsi, kwaye iphule umaleko weseramikhi ngaphakathi, nto leyo ebangela umonakalo kwirola ye-anilox (Umfanekiso 4, Umfanekiso 5).

Umfanekiso 3

Umfanekiso 4

Umfanekiso 5 ukugqwala phantsi kwemakroskopu

Izizathu zokwakheka kokonakala zezi zilandelayo:

① Iimbobo zokwaleka zikhulu, kwaye ulwelo lunokufikelela kwi-base roller ngeembobo, nto leyo ebangela ukugqwala kwe-base roller.

② Ukusetyenziswa ixesha elide kwezinto zokucoca ezifana nee-asidi ezinamandla kunye nee-alkali ezinamandla, ngaphandle kokuhlamba ngexesha elifanelekileyo kunye nokomisa umoya emva kokusetyenziswa.

③ Indlela yokucoca ayichanekanga, ingakumbi xa kucoca izixhobo ixesha elide.

④ Indlela yokugcina ayichanekanga, kwaye igcinwa kwindawo efumileyo ixesha elide.

⑤ Ixabiso le-pH ye-inki okanye izongezo liphezulu kakhulu, ingakumbi i-inki esekwe emanzini.

⑥ Irola ye-anilox iyachaphazeleka ngexesha lokufakelwa kunye nenkqubo yokuqhaqha, nto leyo ebangela utshintsho kwisithuba somda womaleko we-ceramic.

Umsebenzi wokuqala udla ngokungahoywa ngenxa yexesha elide phakathi kokuqala kokugqwala kunye nomonakalo wokugqibela kwi-anilox roll. Ke ngoko, emva kokufumana i-bagging phenomenon ye-ceramic anilox roller, kuya kufuneka uqhagamshelane nomthengisi we-ceramic anilox roller kwangethuba ukuze uphande unobangela we-arch.

Imikrwelo ejikelezayo

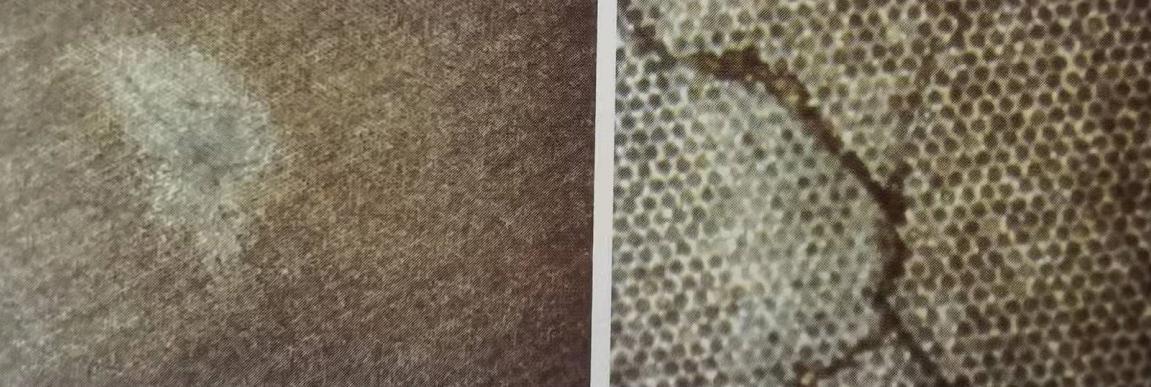

Ukukrweleka kwee-anilox rolls zezona ngxaki zixhaphakileyo ezichaphazela ubomi bee-anilox rolls.(IsiNgesi)umfanekiso 6)Kungenxa yokuba amasuntswana aphakathi kwe-anilox roller kunye ne-doctor blade, phantsi kwesenzo soxinzelelo, aphula i-ceramics yomphezulu we-anilox roller, aze avule zonke iindonga ze-mesh kwicala lokuprinta ukuze enze umngxuma. Ukusebenza kokuprintwa kukubonakala kwemigca emnyama.

Umfanekiso 6 Iroli ye-Anilox enemikrwelo

Ingxaki ephambili yokukrweleka kukutshintsha koxinzelelo phakathi kweblade kagqirha kunye nerola ye-anilox, ukuze uxinzelelo lokuqala lobuso ngobuso lube luxinzelelo lwendawo oluvela kuyo; kwaye isantya esiphezulu sokuprinta sibangela ukuba uxinzelelo lunyuke kakhulu, kwaye amandla okutshabalalisa ayamangalisa. (Umfanekiso 7)

Umfanekiso 7 imikrwelo enzima

Imikrwelo ngokubanzi

imikrwelo emincinci

Ngokubanzi, kuxhomekeke kwisantya sokuprinta, imikrwelo echaphazela ukuprinta iya kwakheka kwimizuzu emi-3 ukuya kweli-10. Zininzi izinto ezitshintsha olu xinzelelo, ikakhulu kwiinkalo ezahlukeneyo: i-anilox roller ngokwayo, ukucocwa nokugcinwa kwenkqubo ye-doctor blade, umgangatho kunye nokufakwa kunye nokusetyenziswa kwe-doctor blade, kunye neziphene zoyilo lwezixhobo.

1. i-anilox roller ngokwayo

(1) Unyango lomphezulu we-ceramic anilox roller alwanelanga emva kokukrola, kwaye umphezulu urhabaxa kwaye kulula ukuwukrwela i-scraper kunye ne-blade ye-scraper.

Umphezulu woqhagamshelwano ne-anilox roller utshintshile, wonyusa uxinzelelo, uphinda-phinda uxinzelelo, kwaye waphula i-mesh kwimeko yokusebenza ngesantya esiphezulu.

Umphezulu werola eboshiweyo wenza imikrwelo.

(2) Umgca onzulu wokupolisha wenziwa ngexesha lokupolisha kunye nenkqubo yokusila kakuhle. Le meko idla ngokubakho xa umqulu we-anilox uziswa, kwaye umgca opolisha kancinci awuchaphazeli ukuprinta. Kule meko, ukuqinisekiswa kokuprinta kufuneka kwenziwe kumatshini.

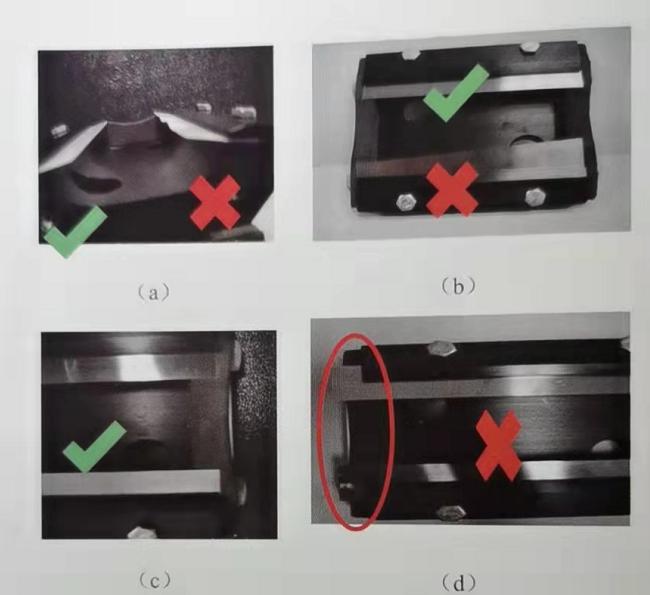

2. ukucocwa nokugcinwa kwenkqubo yeblade kagqirha

(1) Nokuba inqanaba le-chamber doctor blade lilungisiwe, i-chamber doctor blade enezinga eliphantsi iya kubangela uxinzelelo olungalinganiyo. (Umfanekiso 8)

Umfanekiso 8

(2) Nokuba igumbi le-drug blade ligcinwa lithe nkqo, igumbi le-inki elingagungqiyo liya kwandisa umphezulu woqhagamshelwano lwe-blade. Ngokwenene, liya kubangela umonakalo ngqo kwi-anilox roller. Umfanekiso 9

Umfanekiso 9

(3) ukucoca inkqubo yeblade kagqirha kwigumbi kubaluleke kakhulu, Kuthintelwe ukungcola ukuba kungangeni kwinkqubo ye-inki, enamathele phakathi kweblade kagqirha kunye ne-anilox roller. Oku kukhokelela kutshintsho kuxinzelelo. I-inki eyomileyo nayo iyingozi kakhulu.

3. Ukufakelwa nokusetyenziswa kweblade kagqirha

(1) Faka iblade yegumbi ngokuchanekileyo ukuqinisekisa ukuba iblade ayonakalanga, iblade ithe tye ngaphandle kwamaza, kwaye idityaniswe ngokugqibeleleyo nesiphathi seblade, esifana

Njengoko kubonisiwe kuMfanekiso 10, qiniseka ukuba ugcina uxinzelelo lulingana nomphezulu werola ye-anilox.

Umfanekiso 10

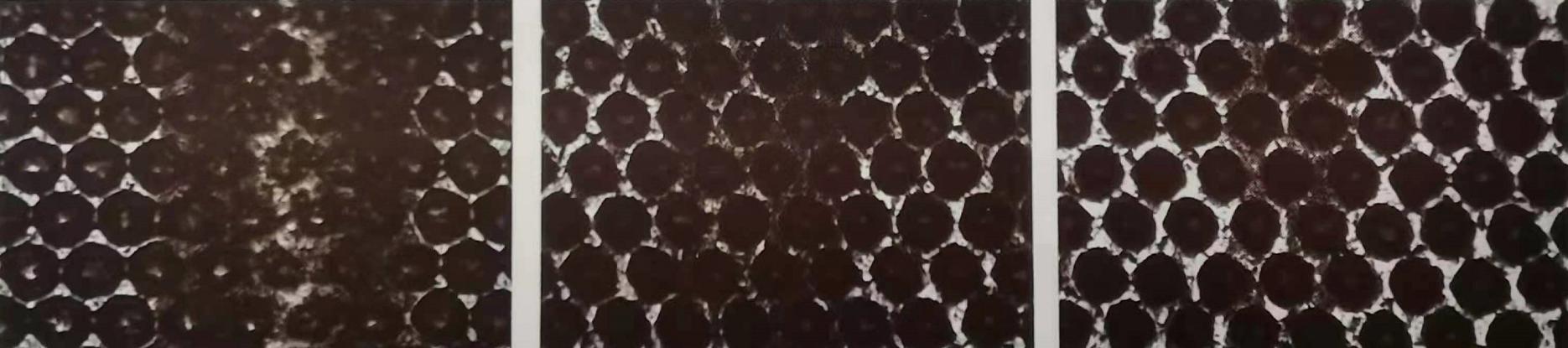

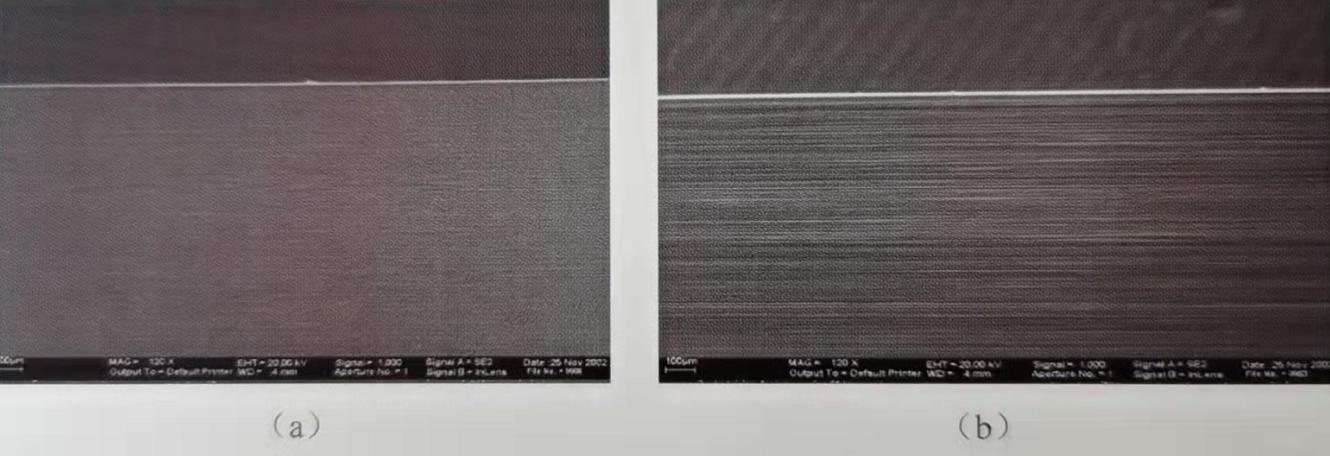

(2) Sebenzisa izikrweqe ezikumgangatho ophezulu. Intsimbi yesikrweqe esemgangathweni ophezulu inesakhiwo esiqinileyo semolekyuli, njengoko kubonisiwe kuMfanekiso 11 (a), emva kokuguguleka. Amasuntswana mancinci kwaye ayafana; isakhiwo semolekyuli sentsimbi yesikrweqe ekumgangatho ophantsi asiqinile ngokwaneleyo, kwaye amasuntswana makhulu emva kokuguguleka, njengoko kubonisiwe kuMfanekiso 11 (b) obonisiweyo.

Umfanekiso 11

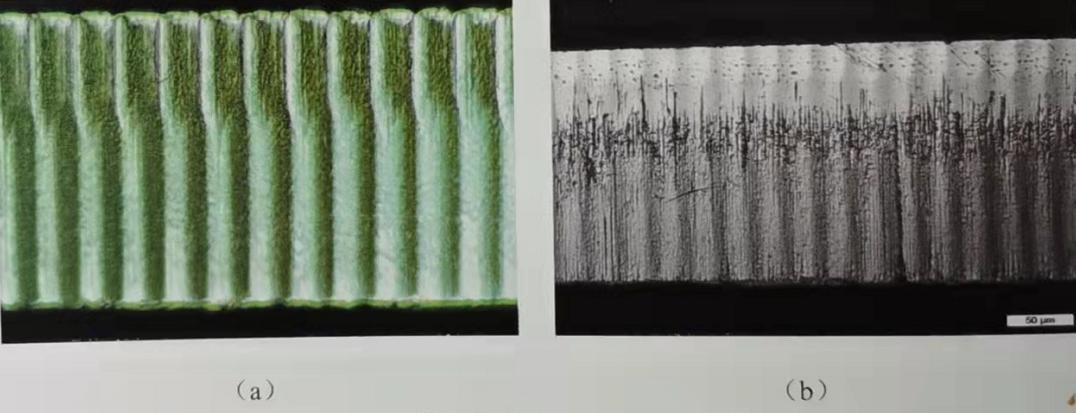

(3) Buyisela imela yeblade ngexesha. Xa utshintsha, qaphela ukukhusela umphetho wemela ekungqubekeni. Xa utshintsha inombolo eyahlukileyo yomgca werola ye-anilox, kufuneka utshintshe imela yeblade. Ubungakanani bokuguguleka kwerola ye-anilox enamanani ahlukeneyo omgca abuhambelani, njengoko kubonisiwe kuMfanekiso 12, umfanekiso wasekhohlo sisikrini senombolo yomgca ophantsi Ukusila imela yeblade kwimela yeblade Imeko yobuso besiphelo obonakeleyo, umfanekiso ongasekunene ubonisa imeko yobuso besiphelo obugugulekileyo berola ye-anilox ebala umgca ophezulu kwimela yeblade. Umphezulu woqhagamshelwano phakathi kwemela yegqirha kunye nerola ye-anilox enamanqanaba okuguguleka angalinganiyo uyatshintsha, nto leyo ebangela utshintsho loxinzelelo kunye nemikrwelo.

Umfanekiso 12

(4) Uxinzelelo lwe-squeegee kufuneka lube lula, kwaye uxinzelelo olugqithisileyo lwe-squeegee luya kutshintsha indawo yoqhagamshelwano kunye ne-engile ye-squeegee kunye ne-anilox roller, njengoko kubonisiwe kuMfanekiso 13. Kulula ukufaka ukungcola, kwaye ukungcola okufakwe ngaphakathi kuya kubangela imikrwelo emva kokutshintsha uxinzelelo. Xa kusetyenziswa uxinzelelo olungenangqiqo, kuya kubakho imisila yesinyithi egugileyo kwicandelo elinqamlezileyo le-scraper etshintshiweyo Umfanekiso 14. Nje ukuba iwe, ibanjwa phakathi kwe-scraper kunye ne-anilox roller, enokubangela imikrwelo kwi-anilox roller.

Umfanekiso 13

Umfanekiso 14

4. iziphene zoyilo lwezixhobo

Iziphene zoyilo zinokubangela ukuba kwenzeke imikrwelo ngokulula, njengokungalingani phakathi koyilo lwebhloko yeinki kunye nobubanzi beroli ye-anilox. Uyilo olungenangqiqo lwe-engile ye-squeegee, ukungangqinelani phakathi kobubanzi kunye nobude beroli ye-anilox, njl.njl., kuya kuzisa izinto ezingaqinisekanga. Kuyabonakala ukuba ingxaki yokukrwela kwicala elijikelezileyo leroli ye-anilox inzima kakhulu. Ukuthathela ingqalelo utshintsho kuxinzelelo, ukucoca kunye nokugcinwa ngexesha, ukukhetha i-scraper efanelekileyo, kunye nemikhwa yokusebenza elungileyo necwangcisiweyo kunokunciphisa kakhulu ingxaki yokukrwela.

Ukungqubana

Nangona ubunzima beeseramikhi buphezulu, zizinto ezibuthathaka. Phantsi kwempembelelo yamandla angaphandle, iiseramikhi kulula ukuziwisa kwaye zenze imingxunya (Umfanekiso 15). Ngokubanzi, kuvela amaqhuma xa kulayishwa kwaye kukhutshelwa iirola ze-anilox, okanye izixhobo zesinyithi ziwela kumphezulu werola. Zama ukugcina indawo yokuprinta icocekile, kwaye uphephe ukufaka iindawo ezincinci ezijikeleze umatshini wokuprinta, ingakumbi kufutshane netreyi ye-inki kunye nerola ye-anilox. Kucetyiswa ukuba wenze umsebenzi olungileyo we-anilox. Ukhuseleko olufanelekileyo lwerola ukuthintela izinto ezincinci ukuba zingawi kwaye zingqubane nerola ye-anilox. Xa ulayisha kwaye ukhutshelwa irola ye-anilox, kucetyiswa ukuba uyisonge ngesigqubuthelo esiguquguqukayo sokukhusela ngaphambi kokuba usebenze.

Umfanekiso 15

Ixesha lokuthumela: Februwari-23-2022