Ukuvaleka kweeseli ze-anilox roller eneneni sesona sihloko singenakuthintelwa ekusebenziseni i-anilox rollers, Ukubonakaliswa kwayo kwahlulahlulwe ngamatyala amabini: ukuvaleka komphezulu we-anilox roller.Umzobo.1) kunye nokuvalwa kweeseli ze-anilox (Umfanekiso.2).

Umfanekiso .1

Umfanekiso .2

Inkqubo ye-inki ye-flexo eqhelekileyo iquka igumbi le-inki (inkqubo yokutya ye-inki evaliweyo), i-anilox roller, i-plate cylinder kunye ne-substrate, Kuyimfuneko ukuseka inkqubo yokutshintshwa kwe-inki ezinzileyo phakathi kwe-inki Chamber, iiseli ze-anilox roller, umphezulu wokushicilela. amachaphaza epleyiti kunye nomphezulu we-substrate ukuze ufumane ushicilelo oluphezulu.Kulo mzila wokudluliselwa kwe-inki, izinga lokudluliselwa kwe-inki ukusuka kumqulu we-anilox ukuya kwi-plate surface malunga ne-40%, ukuhanjiswa kwe-Ink kwi-plate ukuya kwi-substrate malunga ne-50%, kunokubonwa ukuba ukudluliselwa kwendlela ye-inki ayikho ukudluliselwa komzimba okulula, kodwa inkqubo entsonkothileyo ebandakanya ukudluliselwa kwe-inki, ukomiswa kwe-inki, kunye nokuchithwa kwakhona kwe-inki;Njengoko isantya soshicilelo somatshini wokushicilela we-flexo sikhula ngokukhawuleza kwaye ngokukhawuleza, le nkqubo eyinkimbinkimbi ayiyi kuba yinto enzima ngakumbi, kodwa kunye nokuphindaphinda kokuguquguquka kwindlela yokuhanjiswa kwendlela ye-inki iya kuba ngokukhawuleza kwaye ngokukhawuleza;Iimfuno zeempawu ezibonakalayo zemingxuma nazo ziya zinyuka kwaye ziphezulu.

Iipolymers ezine-cross-linking mechanism zisetyenziswa ngokubanzi kwii-inki, ezifana ne-polyurethane, i-acrylic resin, njl., Ukuphucula ukubambelela, ukuxhathisa i-abrasion, ukuxhathisa kwamanzi kunye nokuxhathisa imichiza ye-inki layer.Ekubeni ireyithi yokudlulisa inki kwiiseli ze-anilox roller kuphela 40% , Oko kukuthi, ininzi ye-inki kwiiseli ngokwenene ihlala ezantsi kweeseli ngexesha lenkqubo yonke yokushicilela.Nokuba inxalenye ye-inki itshintshwe, kulula ukubangela ukuba i-inki igqitywe kwiiseli.I-resin cross-linking yenziwa kumphezulu we-substrate, ekhokelela ekuvinjweni kweeseli ze-anilox roll.

Kulula ukuqonda ukuba ubuso be-anilox roller buvaliwe.Ngokuqhelekileyo, i-anilox roller isetyenziswe ngendlela engafanelekanga, ukwenzela ukuba i-inki iphiliswe kwaye idibaniswe ne-cross-link ebusweni be-anilox roller, okubangelwa ukuvala.

Kubenzi be-anilox roll, uphando kunye nophuhliso lwetekhnoloji yokwambathisa nge-ceramic, ukuphuculwa kwetekhnoloji yesicelo selaser, kunye nokuphuculwa kwetekhnoloji yonyango lomphezulu we-ceramic emva kokukrolwa kwemiqulu ye-anilox kunokunciphisa ukuvaleka kweeseli ze-anilox.Okwangoku, iindlela ezisetyenziswa ngokuqhelekileyo kukunciphisa ububanzi bodonga lwe-mesh, ukuphucula ukuguquguquka kodonga lwangaphakathi lwe-mesh, kunye nokuphucula ukuhambelana kwengubo ye-ceramic..

Kumashishini oshicilelo, isantya sokumisa i-inki, u-resolubility, kunye nomgama ukusuka kwindawo ye-squeegee ukuya kwindawo yokuprinta nayo inokulungiswa ukunciphisa ukuvaleka kweeseli ze-anilox roller.

Ukonakala

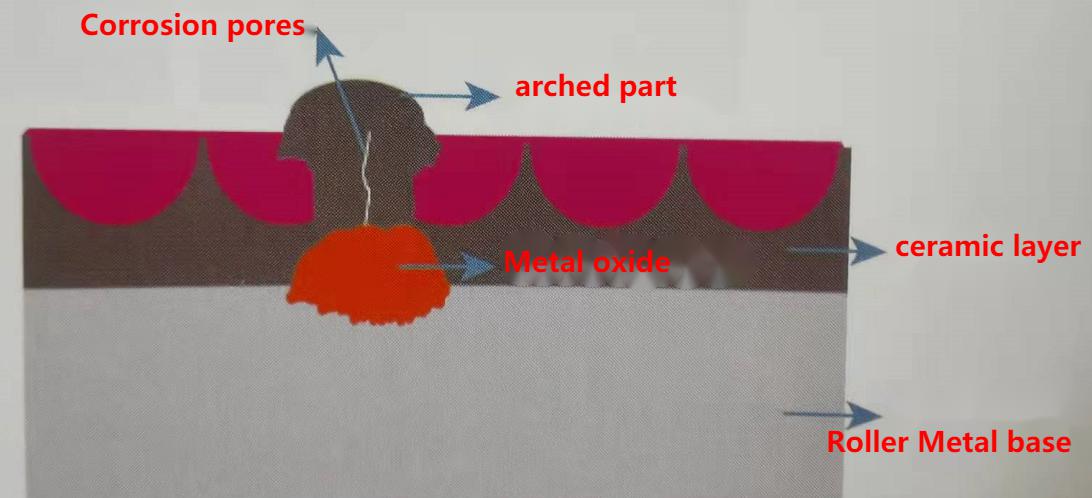

I-Corrosion ibhekisela kwi-phenomenon ye-point-like protrusions ebusweni be-anilox roller, njengoko kuboniswe kuMzobo 3. I-Corrosion ibangelwa i-arhente yokucoca ingena ngaphakathi kwinqanaba elisezantsi kunye ne-gap ye-ceramic, i-corroding i-roller yesiseko sesinyithi esisezantsi, kunye nokuphula umaleko we-ceramic ukusuka ngaphakathi, obangela umonakalo kwi-roller ye-anilox (Umfanekiso 4, umzobo 5).

Umfanekiso wesi-3

Umzobo 4

Umzobo we-5 ukubola phantsi kwe-microscope

Izizathu zokwenza umhlwa zezi zilandelayo:

① Iipores zengubo zikhulu, kwaye ulwelo lunokufikelela kwi-roller yesiseko ngokusebenzisa iipores, kubangela ukubola kwe-roller yesiseko.

② Ukusetyenziswa kwexesha elide lezinto zokucoca ezifana ne-acids eqinile kunye ne-alkalis eqinile, ngaphandle kokuhlamba ngexesha kunye nokumisa umoya emva kokusetyenziswa.

③ Indlela yokucoca ayilunganga, ngakumbi kwisixhobo sokucoca ixesha elide.

④ Indlela yokugcina ayilunganga, kwaye igcinwa kwindawo efumileyo ixesha elide.

⑤ Ixabiso le-pH le-inki okanye izongezo liphezulu kakhulu, ngakumbi i-inki esekwe emanzini.

⑥ I-anilox roller inefuthe ngexesha lofakelo kunye nenkqubo yokuqhaqha, okukhokelela ekutshintsheni kwesithuba se-ceramic layer.

Umsebenzi wokuqala udla ngokungahoywa ngenxa yexesha elide phakathi kokuqala kokubola kunye nomonakalo ekugqibeleni kwi-anilox roll.Ngoko ke, emva kokufumana i-bagging phenomenon ye-ceramic anilox roller, kufuneka uqhagamshelane nomthengisi we-ceramic anilox roller ngexesha lokuphanda imbangela ye-arch.

Imikrwelo ejikelezayo

Imikrwelo yee-anilox rolls zezona ngxaki zixhaphakileyo ezichaphazela ubomi be-anilox rolls.(umfanekiso 6)Kungenxa yokuba amaqhekeza phakathi kwe-anilox roller kunye ne-blade ugqirha, phantsi kwesenzo soxinzelelo, aphule i-ceramics yomhlaba we-anilox roller, kwaye avule zonke iindonga ze-mesh kwindlela yokuprinta yokuqhuba ukwenza i-groove.Ukusebenza kushicilelo kukubonakala kwemigca emnyama.

Umzobo we-6 i-Anilox roll kunye nemikrwelo

Ingxaki ephambili yokukrazula kukutshintsha koxinzelelo phakathi kogqirha kunye ne-anilox roller, ukwenzela ukuba i-original face-to-face pressure ibe yingcinezelo yendawo yendawo;kunye nesantya esiphezulu sokushicilela kubangela ukuba uxinzelelo luphakame ngokukhawuleza, kwaye amandla atshabalalisayo ayamangalisa.(umzobo 7)

Umzobo 7 imikrwelo eqatha

Imikrwelo ngokubanzi

imikrwelo emincinci

Ngokubanzi, ngokuxhomekeke kwisantya soshicilelo, imikrwelo echaphazela ushicilelo iya kwenziwa kwimizuzu emi-3 ukuya kweli-10.Kukho izinto ezininzi ezitshintsha olu xinzelelo, ngokukodwa kwiinkalo ezininzi: i-anilox roller ngokwayo, ukucocwa kunye nokugcinwa kwenkqubo ye-blade ugqirha, umgangatho kunye nofakelo kunye nokusetyenziswa kwe-blade ugqirha, kunye neziphene zokuyila izixhobo.

1.i-anilox roller ngokwayo

(1) Ukulungiswa komphezulu we-ceramic anilox roller akwanelanga emva kokukrolwa, kwaye umphezulu urhabaxa kwaye kulula ukukrwela i-scraper kunye nencakuba ye-scraper.

Indawo yokudibanisa kunye ne-anilox roller itshintshile, yandisa uxinzelelo, iphindaphinda uxinzelelo, kwaye iphule i-mesh kwimeko yokusebenza kwesantya esiphezulu.

Umphezulu we-roller e-embossed wenza imikrwelo.

(2) Umgca wokupolisha onzulu wenziwa ngexesha lokucolwa kunye nenkqubo yokugaya.Le meko ngokuqhelekileyo ikhona xa i-anilox roll ihanjiswa, kwaye umgca ophuculweyo omncinci awuchaphazeli ukuprinta.Kule meko, ukuqinisekiswa kokuprinta kufuneka kuqhutywe kumatshini.

2.ukucoca kunye nokugcinwa kwenkqubo ye-blade kagqirha

(1) Ingaba inqanaba le-blade yegqirha legumbi lilungiswa, i-blade yegqirha yegumbi enezinga elibi liya kubangela uxinzelelo olungalinganiyo.(umzobo 8)

Umzobo 8

(2) Ingaba igumbi le-blade likagqirha ligcinwe ngokuthe nkqo, igumbi le-inki elingaguqukiyo liya kwandisa umphezulu wokudibanisa weblade.Ngokukrakra, kuya kubangela ngokuthe ngqo umonakalo kwi-anilox roller.Umzobo 9

Umzobo 9

(3)igumbi lokucocwa kwecwecwe likagqirha libaluleke kakhulu, Thintela ukungcola ekungeneni kwinkqubo ye-inki, ebambeke phakathi kwecwecwe likagqirha kunye nerola ye-anilox.okubangela utshintsho kuxinzelelo.I-inki eyomileyo nayo iyingozi kakhulu.

3.Ukufakwa kunye nokusetyenziswa kweblade kagqirha

(1) Faka i-blade yegumbi likagqirha ngokuchanekileyo ukuqinisekisa ukuba i-blade ayonakaliswa, i-blade iqondile ngaphandle kwamaza, kwaye idibaniswe ngokugqibeleleyo kunye nesibambi se-blade, njenge

Njengoko kuboniswe kwi-Figure 10, qiniseka ukuba ugcine uxinzelelo nakwindawo ye-anilox roller.

Umfanekiso we-10

(2) Sebenzisa i-scrapers ezikumgangatho ophezulu.I-high-quality scraper steel inesakhiwo esiqinileyo se-molecular, njengoko kuboniswe kwi-Figure 11 (a), emva kokugqoka Iinqununu zincinci kwaye zifana;isakhiwo se-molecular ye-low-quality scraper steel ayiqinile ngokwaneleyo, kwaye iinqununu zikhulu emva kokugqoka, njengoko kuboniswe kuMzobo 11 (b) kubonisiwe.

Umfanekiso we-11

(3) Yitshintshe imela ngexesha.Xa utshintsha, nikela ingqalelo ekukhuseleni umphetho wemela ukuba ungabhubhi.Xa utshintsha inombolo yomgca eyahlukileyo ye-anilox roller, kufuneka ubeke indawo ye-blade knife.Iqondo lokugqoka i-anilox roller kunye neenombolo zomgca ezahlukeneyo azihambelani, njengoko kuboniswe kwi-Figure 12, umfanekiso osekhohlo ngumgca ophantsi inombolo yesikrini Ukugaya i-blade knife kwi-blade knife Isimo sobuso bokuphela owonakalisiweyo, umfanekiso ekunene ibonisa imeko yobuso obunxibileyo bomgca ophezulu wokubala i-anilox roller ukuya kwimela yencakuba.Umphezulu woqhagamshelwano phakathi kwecwecwe likagqirha kunye ne-anilox roller kunye namanqanaba angahambelaniyo okunxiba atshintshayo, okubangela utshintsho loxinzelelo kunye nemikrwelo.

Umfanekiso we-12

(4) Uxinzelelo lwe-squeegee kufuneka lube lula, kwaye uxinzelelo olugqithiseleyo lwe-squeegee luya kutshintsha indawo yokudibanisa kunye ne-angle ye-squeegee kunye ne-anilox roller, njengoko kuboniswe kuMzobo 13. Kulula ukungenisa ukungcola, kunye ne-entrained. ukungcola kuya kubangela imikrwelo emva kokutshintsha uxinzelelo.Xa kusetyenziswe uxinzelelo olungenangqiqo, kuya kubakho imisila yensimbi egqitywe kwi-cross section of the replaced scraper Umfanekiso 14. Emva kokuba iwele, ibanjwe phakathi kwe-scraper kunye ne-anilox roller, enokubangela imikrwelo kwi-anilox roller.

Umfanekiso we-13

Umfanekiso we-14

4.iziphene zoyilo lwezixhobo

Iziphene zoyilo zinokubangela ukuba imikrwelo yenzeke ngokulula, njengokungahambelani phakathi koyilo lwebhloko ye-inki kunye nobubanzi be-anilox roll.Uyilo olungenangqiqo lwe-angle ye-squeegee, ukungahambisani phakathi kobubanzi kunye nobude be-anilox roller, njl., Kuya kuzisa izinto ezingaqinisekanga.Ingabonwa ukuba ingxaki yemikrwelo kwi-circumferential direction ye-anilox roll inzima kakhulu.Ukunika ingqalelo kwiinguqu zoxinzelelo, ukucocwa kunye nokugcinwa kwexesha, ukukhetha i-scraper efanelekileyo, kunye nemikhwa emihle kunye nocwangco yokusebenza kunokunciphisa kakhulu ingxaki yokukrala.

Ukungqubana

Nangona ukuqina kweekeramics kuphezulu, zizinto ezinqabileyo.Ngaphantsi kwempembelelo yamandla angaphandle, i-ceramics kulula ukuwa kwaye ivelise imigodi (Umfanekiso 15).Ngokuqhelekileyo, ama-bumps ayenzeka xa ulayisha kwaye ukhulula i-anilox rollers, okanye izixhobo zetsimbi ziwela kumphezulu we-roller.Zama ukugcina indawo yokushicilela icocekile, kwaye ugweme ukupakisha iindawo ezincinci kumatshini wokushicilela, ngakumbi kufutshane netreyi ye-inki kunye ne-anilox roller.Kunconywa ukwenza umsebenzi omhle we-anilox.Ukukhuselwa ngokufanelekileyo kwe-roller ukukhusela izinto ezincinci zokuwa kunye nokungqubana ne-anilox roller.Xa ulayisha kwaye ukhulula i-roller ye-anilox, kucetyiswa ukuba uyisonge nge-flexible cover cover ngaphambi kokusebenza.

Umfanekiso we-15

Ixesha lokuposa: Feb-23-2022