Ukugcinwa kwemihla ngemihla komatshini wokuprinta we-flexo ongenagiya kufuneka kugxile ekukhuseleni ukucoca kunye nokugcinwa kwenkqubo. Njengesixhobo esichanekileyo, ukucoca kunye nokugcinwa komatshini wokuprinta we-flexographic kufuneka kwenziwe kuyo yonke ikhonkco lemveliso. Emva kokumisa, intsalela ye-inki yeyunithi yokuprinta, ngakumbi i-anilox roller, i-plate roller kunye nenkqubo ye-scraper, kufuneka isuswe ngoko nangoko ukuze kuthintelwe ukuvaleka okomileyo kwaye kuchaphazele ukufana kokudluliselwa kwe-inki.

Xa kucocwa, kufuneka kusetyenziswe izinto zokucoca ezikhethekileyo kunye nelaphu elithambileyo ukusula ngobunono imingxunya ye-anilox roller mesh ukuthintela izinto eziqinileyo ukuba zingawonakalisi isakhiwo sayo esibuthathaka. Ukususwa kothuli kumphezulu womzimba womatshini, ii-guide rails kunye nee-servo motor heat dissipation ports nako kubalulekile ukuqinisekisa ukutshatyalaliswa kobushushu okugudileyo kunye nokuhamba okuzinzileyo koomatshini. Ukugcinwa kwe-lubrication kufuneka kulandele ngokungqongqo iinkcukacha zezixhobo, kwaye kongezwe rhoqo i-grease echaziweyo kwii-guide rails, ii-bearings kunye nezinye izinto ukunciphisa ukulahleka kokungqubana kunye nokugcina ukuchaneka kwexesha elide komatshini wokuprinta we-flexographic. Ukongeza, ukuhlolwa kwemihla ngemihla kokutywinwa kwemibhobho ye-pneumatic kunye nokuqokelelwa kothuli kwiikhabhathi zombane kunokuthintela ngempumelelo ukungaphumeleli ngequbuliso.

Uzinzo lwenkqubo yomatshini wokuprinta we-flexographic luxhomekeke kulondolozo oluphindwe kabini lwehardware kunye nesoftware. Nangona isakhiwo sokudlulisa esingenagiya senza kube lula ubunzima boomatshini, kusafuneka ukujonga rhoqo ukuqina kwemoto ye-servo kunye noxinzelelo lwebhanti ehambelanayo ukuze kuthintelwe ukukhululeka kunye nokuphambuka kobhaliso. Ngokwenkqubo yolawulo, kuyimfuneko ukujonga iiparameter ze-servo drive ngexesha langempela kunye nokulinganisa inkqubo yobhaliso. Uvakalelo lwe-tension sensor kunye nesixhobo sokunyuswa kwe-vacuum pressure luchaphazela ngokuthe ngqo ukuhanjiswa kwezinto, kwaye ukucoca kwemihla ngemihla kunye novavanyo olusebenzayo kubalulekile. Ekusetyenzisweni kwexesha elide, ulawulo lwezinto ezisetyenziswayo lweprinta ye-flexographic lubaluleke ngokulinganayo, njengokutshintshwa ngexesha elifanelekileyo kwee-scraper blades kunye neetyhubhu ze-inki ezindala, kunye nokugcinwa rhoqo kweeparameter zezixhobo ukujongana nokungahambi kakuhle kwedatha. Ulawulo lobushushu kunye nokufuma kwindawo yokusebenzela lunokunciphisa ukuguquguquka kwezinto kunye nokuphazamiseka kwe-electrostatic, kwaye luphucule ngakumbi isiphumo sokuprinta. Kuphela ngamaqhinga okugcina esayensi kunye nenkqubo apho ii-printa ze-flexographic ziqhubeka nokusebenzisa izibonelelo zazo zokuchaneka okuphezulu kunye nokusebenza kakuhle, ngelixa zigcina imizamo yokwenza ngcono ulwakhiwo kunye nophuhliso lwetekhnoloji ngaphakathi kwenkqubo yokushicilela-yokupakisha yemizi-mveliso.

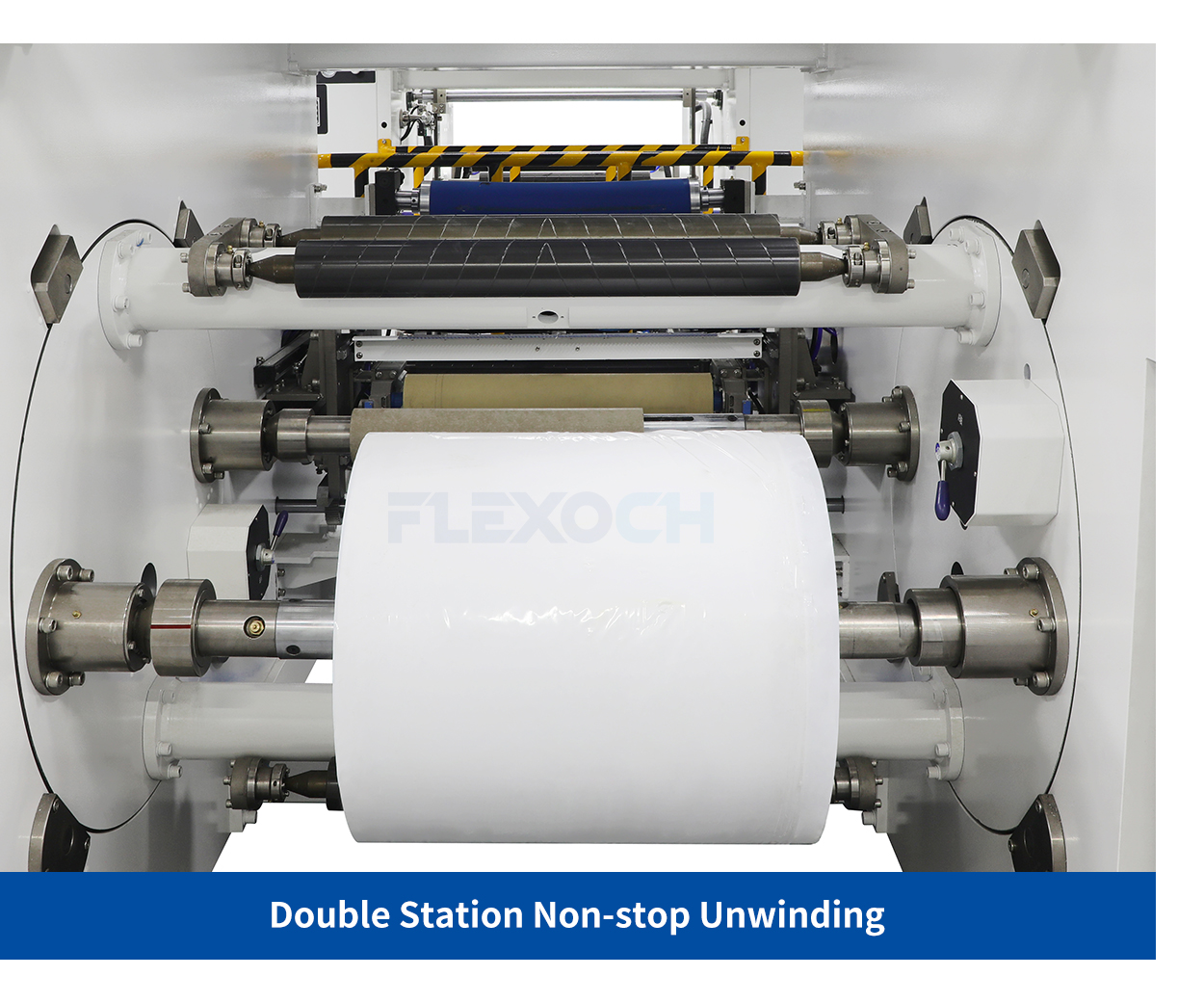

Umboniso weenkcukacha zomshicileli wokuprinta we-flexo ongenaGearless

Ixesha leposi: Epreli-11-2025